Thermoplastic high-performance composite components for the aerospace industry

ENGEL, FACC, Ensinger and Neue Materialien Fürth are jointly presenting the integrated production of a load-bearing aerospace component based on high-temperature resistant organic sheets for the first time at JEC World 2023. For the design and targeted prediction of processing conditions and component properties, SIGMASOFT and Neue Materialien Fürth simulated the application in advance. The result: amazing process accuracy and component prediction.

Thermoplastic material used throughout

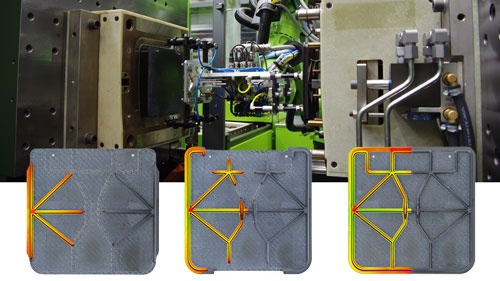

Thermoset materials are increasingly being substituted by thermoplastics in all areas of mobility, including the aviation industry. Drivers of this development include increasing cost pressure and sustainability. The consistent approach on using thermoplastic materials enables a very high degree of process integration for simple functionalization of components, which can further reduce the required time, the raw material input and the energy demand. A consortium of the know-how partners ENGEL (Schwertberg, Austria), FACC (Ried im Innkreis, Austria), Ensinger (Nufringen, Germany), Victrex (Lancashire, UK) and Kuraray (Hattersheim am Main, Germany), SIGMA Engineering GmbH (Aachen, Germany) and Neue Materialien Fürth GmbH (Fürth, Germany) developed a machine exhibit to demonstrate the great potential of thermoplastic lightweight technology in the aerospace industry live at JEC World 2023 from April 25th to 27th, 2023, in Paris. An ENGEL victory 660/160 injection molding machine will be used for the automated production of inspection flaps for passenger aircraft fuselages (lead picture). The production cell includes an Engel easix jointed-arm robot and an Engel IR oven, which heats near-net-shape organic sheets made of PAEK matrix, places them in the mold and overmolds them directly in the injection molding process. Stiffening ribs and an assembly clip are formed and the rework-free component is removed.

Targeted design through simulative design

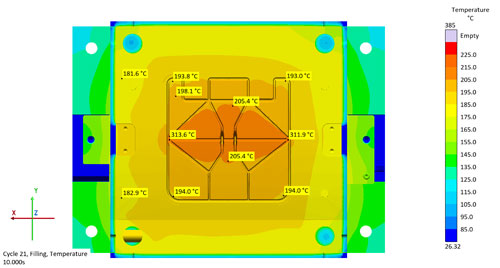

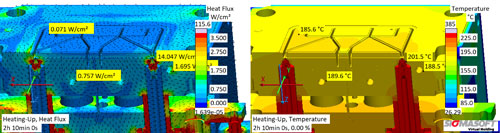

If materials are to be substituted for existing applications for sustainability and cost reasons, the question arises as to how the processes can be designed in advance to be as energy- and cost-efficient as possible for the customer. In this context, simulative design is an important tool for minimizing machine trials and the time required to start up series production. Modern simulation approaches take into account not only the component, but also the mold with all components and the complete process with all auxiliary times over several cycles. In this way, the production conditions are completely simulated on the computer in advance, and lengthy trial-and-error tests on the machine are reduced to a minimum. The complete mold, including temperature control channels, is also taken into account in the simulation for the inspection flap. During the simulation, the flap is first heated up for 130 minutes and then brought to a thermally stable state over 20 heating cycles (Fig. 2). In a subsequent production cycle, the inspection flap is injected, cooled down and demolded as in real production. In this process, the rib structure is applied to the organic sheet, which is preheated to 340 °C. This also allows the analysis of the interactions between organic sheet and ribs.

By analyzing the mold, it is possible to visualize not only the temperature behavior over several cycles, but also the heat flow between the mold components (Fig. 3 left) and the heating phase (Fig. 3 right). In the case of the heat flow, it is possible to see how it moves in the direction of the cavity. With the aid of such a detailed view, the location of potentially occurring hot or cold spots can be identified, for example. Since, in this case, ribs are injected onto an organic sheet, not only is the suitable temperature important for good adhesion properties, but also the identification of sink marks.

Process optimization - comparison of reality and simulation

With regard to process optimization, the use of simulation is also useful. A virtual cycle time optimization carried out in advance can be transferred to the real process. This not only speeds up the sampling process, but also the subsequent (series) production. In this way, the mold can already be sampled virtually, which can also have a positive influence on the running times of the machine. It is important to superimpose simulation results with reality, e.g. during sampling, it can already help to uncover differences that can still be eliminated. In most cases, there is a high degree of agreement between the data and reality. Fig. 4 shows an example of short shots compared with simulation results, the partial fillings being 33, 66 and 100 %. The simulation is shown on the left and the partial filling on the right.

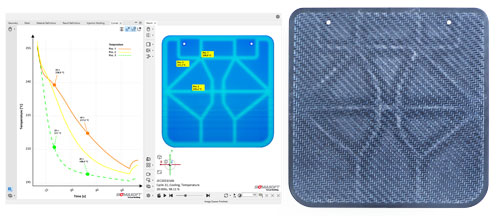

If the temperature distribution on the visible side of the organic sheet is observed during the filling and holding pressure phase, the injected rib structure is also clearly visible on this side. Temperature differences of 20 - 30 °C over a period of more than 20 s provide an indication that the rib structure will also be visible on the visible side of the finished part. The following figure shows an example of the temperature curves at the three marked positions on the visible side of the organic sheet.

Further analyses of the temperature and pressure conditions during the filling and holding pressure phases also allow the user to make an initial assessment regarding the quality of the adhesion between the rib structure and the organic sheet.

Conclusion

The results of the simulation help to eliminate weak points and optimize process sequences already during the design of continuous fiber-reinforced components. The simulative mapping of the entire mold also allows heat flows to be detected in advance and thus helps to improve quality at critical points in a targeted manner. We cordially invite you to form your own impression of our competence and to examine the live demonstration on site. We are open to your future ideas and projects and can support you in your developments. Please contact us, we are looking forward to your visit.

You will find the production cell at the Engel booth in Hall 5 at Booth N79. For more information on the project, visit Neue Materialien Fürth at the Bayern Innovativ joint booth in Hall 6, Booth R32.