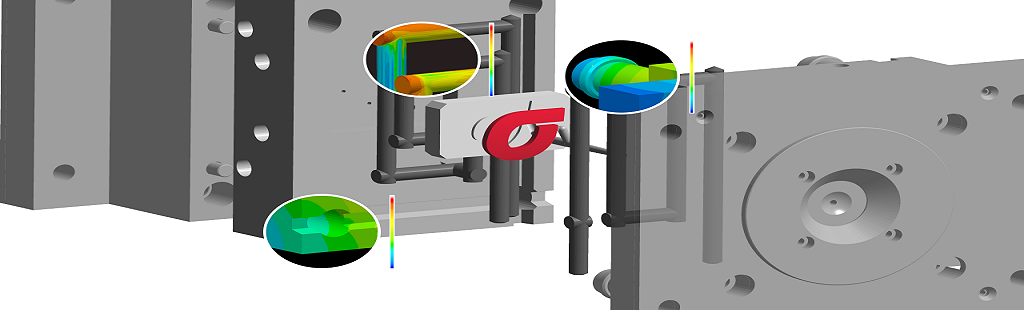

Our team of experts will use the full range of the SIGMASOFT® product portfolio to provide simulation solutions best fit to your needs so as to help you overcome your capacity bottlenecks and extend your process expertise. Specifically, we can help you to:

- Optimise product design to improve quality and reduce defects

- Identify the correct location of cooling channels and heating cartridges

- Establish optimised process parameters

- Identify all possibilities to reduce cycle time and thus reduce production costs

- Understand the thermal behaviour of the mold

With our knowledge and excellent service, we help developers and designers learn to identify the possible production bottlenecks and the critical behaviour of the parts before prototyping it so as to shorten the entire development cycle, reduce material wastage and minimize the risks imposed.

Tool makers will witness having the optimum design of mold tempering, runner system, hot & cold runners and ejector packages in their first attempt!

With Virtual Molding, molders can easily achieve ideal production parameters to realize the desired part quality and productivity.

As a whole, SIGMAproject delivers sound information to aid accurate and reliable decision-making. For the fullest potential of SIGMASOFT® simulation results, we will present our findings on the following:

- Project report in PPT and/or PDF

- Online presentation

- Onsite presentation

- Discuss and conclude on the further steps

- SIGMAinteract files

Discover the hidden potentials with our unique approach for the simulation of injection molding processes with SIGMASOFT® Virtual Molding today!

CONTACT

Would you like to know more about our SIGMAproject Engineering Service?

Tel: +65 6564 3435

E-mail: Show email